Description

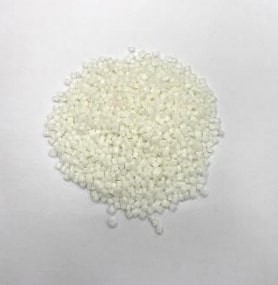

Injection Molding PC/ABS+GF30%

PCR(Post-Consumer Recycled Material) 30%, High Stiffness

Application: General Purpose, Automotive Interior, Trim

Properites |

Test condition | Test Method | Unit |

Typical Value |

| Physical |

|

|

|

|

| Specific Gravity |

|

ISO 1183 |

g/cm³

|

1.34 |

| Molding Shrinkage |

|

ISO 294-4 | % | 0.1-0.3 |

| Melt Flow Rate |

260℃ / 5kg

|

ISO 1133 |

g/10min

|

10 |

| Mechanical |

|

|

|

|

|

Tensile Strength

@ Yield

|

50mm/min |

ISO 527 |

Mpa | 120 |

|

Tensile Elongation

@ Break

|

50mm/min |

ISO 527 |

Mpa | 1.4 |

|

Flexural Strength Flexural Modulus |

2mm/min 2mm/min |

ISO 178 ISO 178 |

Mpa Mpa |

165 7,300 |

|

Charpy Impact Strength (Notched) |

23℃

-30℃

|

ISO 179 |

KJ/m²

KJ/m²

|

10 8 |

| Thermal |

|

|

|

|

|

Heat Deflection Temperature

(Unannealed, Flatwise)

|

1.8Mpa |

ISO 75

|

℃

|

115

|

| Vicat Softening Temperature |

5daN, 50℃/h

|

ISO 306 |

℃ |

120 |

Processing Guide (Injection Molding)

| Processing Parameters | Unit | Value |

| Drying Temperature |

℃

|

85-100 |

| Drying Time | hrs | 4-6 |

| Maximum Moisture Content | % | 0.02 |

| Melt Temperature |

℃ |

235-265 |

|

Front Cylinder Temperature Middle Rear |

℃ ℃ ℃ |

220 ~ 240 235 ~ 255 245 ~ 275 |

| Nozzle Temperature |

℃ |

250~ 265 |

| Mold Temperature |

℃ |

50~ 80 |

| Back Pressure |

kg/cm2

|

|

| Screw Speed | rpm | 40~ 70 |